| Dimensions | Any Custom Size/Style/Shape/Design |

| Printing | CMYK, PMS, Digital and Plain (Non-Printed) |

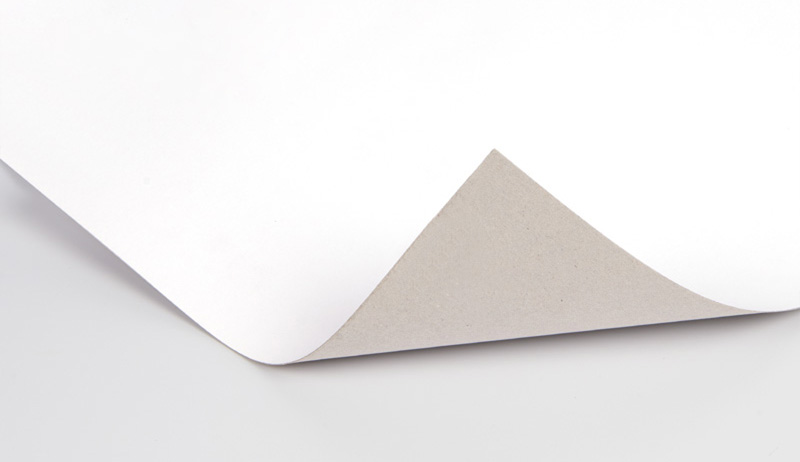

| Card Stock | 10pt to 28pt Kraft, Cardboard, Corrugated and Colored Stock. |

| Quantities | 50 boxes to start with |

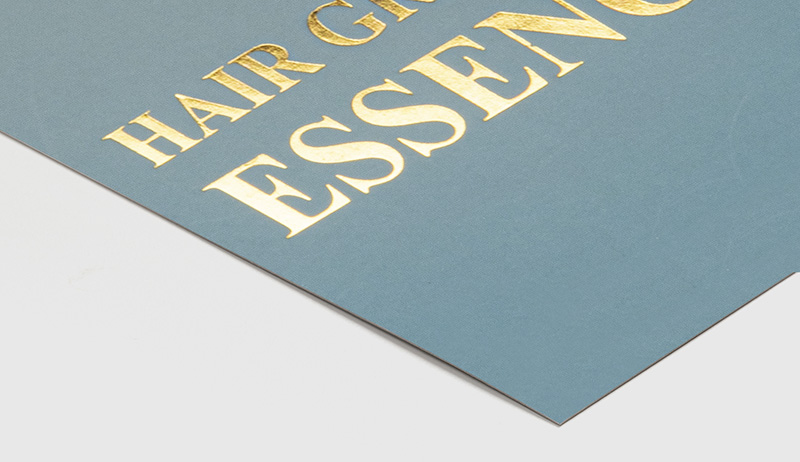

| Add – On | Custom Die Cut Window, Silver/Gold Foiling, Embossing, Stamping. |

| Proofing | Flat View, 3D Digital Proofing, Physical Sampling (On request) |

| Coating/Finish | Gloss Finish, Matte Finish, Spot UV, Spread UV and Blind UV etc… |

| Default Process | Die Cutting, Gluing, Scoring, Pasted, Assembled and Flat Ship |

| Turn Around Time | 4-6 Business Day to Dispatch, Rush/Expedite |

Custom Milk Cartons

You are certainly launching new milk products and have much knowledge about the competition. But there are lots of factors that you need to learn. Packaging is one of those factors that showcase the real value of the milk products and educate the consumers. For this, many dairy companies are using custom milk cartons that likely to say a marketing and worth of the milk products.

Why it’s crucial to get the right packaging?

Milk box packaging plays a crucial role in the success of the dairy brand. In many cases, the custom milk cartons create a recognition and value impression in the brands. Understanding this role, we at Custom Packaging Hub provide help to share the brand’s value in the packaging design. Our designers always looking for fresh and durable packaging materials that a way to draw a durable appeal into milk cartons. The milk products require a signature blend of well-built materials that add an exclusive look to the packaging. So, we are utilizing original cardboard, cardstock, and bux board materials that are best to design high-quality milk cartons.

What is the importance of milk box packaging?

If you’re in the dairy industry, it might be difficult to build a stand-out position next to the competition. But when you try out something new in the printed milk cartons, you get a chance to make a fearless and bold marketing statement. Thus, the retail companies should get a new chance to develop friendly marketing ideas. If you are willing to succeed, then get our help as our experts predict some new and wonderful marketing trends to boost your sales. This is why we promise to bring playful marketing designs that work at the core to meet the consumers’ expectations.

- Top-notch printing ideas

After you have determined the best materials, it’s time to work on the packaging design. Here we can help you and provide handy printing ideas and make proper research on the competitors. We know that colors are a critical factor to design an appealing box. For this, we use the CMYK, PMS methods which are the best ways to add proper branding into the box’s design.

- Knowing finishing ideas

Remember that accurate and creative printing and designing in the milk box packaging can only convey the true value of the milk products. If you desire to keep the milk products in the front of consumers’ minds, then add simple and luxurious appeal into these boxes. We know that colors, themes, and graphics in custom milk cartons present an alluring impression of the brand. Thus, we take advantage of modern printing by using these finishing details:

- Lamination

- Embossing

- AQ coating

- Foiling

As a final look, we are never afraid of using the new and trendy printing ideas that change the consumers’ perception of dairy products.

What set us apart?

Custom Packaging Hub creates a big differentiator to convey the real value of the retail companies. We understand how to set your brand different from your rivals. In other words, we must convey the valuable feel of the brand through custom milk cartons. Yes, we promise to offer the best customers shopping experience at affordable prices.